Manual Transmission Repair: A Comprehensive Plan

Navigating diverse manuals—from diesel engines to lawnmowers and Bluetooth earbuds—highlights the need for focused, detailed guides like this one, dedicated to manual transmission repair.

Manual transmissions, a cornerstone of automotive engineering, offer drivers direct control over gear selection and engine RPM. Unlike automatic systems, they rely on a driver-operated clutch and a series of gears to transfer power from the engine to the wheels. Understanding their fundamental principles is crucial for effective repair.

This system, while mechanically simpler than automatics, demands precise operation and maintenance. The availability of diverse manuals – spanning from complex diesel engines to simpler lawnmowers – underscores the importance of specialized documentation. Proper diagnosis and repair require familiarity with components like gearsets, synchronizers, and the clutch mechanism.

This guide aims to provide a comprehensive overview, mirroring the detailed approach found in quality service manuals, ensuring both novice and experienced mechanics can confidently tackle manual transmission repairs.

II. Tools and Equipment Required

Successful manual transmission repair necessitates a well-equipped workspace and a range of specialized tools. Beyond standard mechanics’ sets, essential items include a transmission jack for safe removal and installation, and a comprehensive socket set, encompassing both metric and standard sizes.

Specialized pullers are vital for removing gears and bearings, while a clutch alignment tool ensures proper disc centering during reassembly. Diagnostic equipment, like multimeters, aids in electrical testing. Access to detailed manuals, similar to those for engines or lawn equipment, is paramount.

Furthermore, torque wrenches are crucial for tightening fasteners to specified values, preventing damage. Safety gear, including gloves and eye protection, is non-negotiable.

III. Common Manual Transmission Problems

Manual transmissions, while robust, are susceptible to several common issues. Clutch-related problems frequently manifest as slipping during acceleration, dragging when shifting, or unusual noises. Shifting difficulties, including trouble engaging gears or experiencing grinding sounds, are also prevalent.

Fluid leaks, often stemming from worn seals, require identifying the correct fluid type – a detail emphasized in various equipment manuals. Internal wear within the transmission can cause popping out of gear or complete failure. Diagnosing these issues often requires a systematic approach, much like troubleshooting any complex system, referencing detailed guides when available.

III.A. Clutch Issues: Slipping, Dragging, and Noise

Clutch slippage, characterized by engine revving without proportional speed increase, often indicates a worn clutch disc. Dragging, where the clutch doesn’t fully disengage, causes shifting difficulty and potential grinding. Unusual noises – squealing, chattering, or rattling – can signal a failing throw-out bearing or pressure plate.

These issues frequently stem from contamination, wear, or improper adjustment. Detailed manuals, like those for diesel engines, emphasize meticulous maintenance to prevent premature failure. Proper diagnosis requires inspecting the disc’s friction material, the pressure plate’s springs, and the bearing’s condition, mirroring the thoroughness found in comprehensive service documentation.

III.B. Shifting Problems: Difficulty Engaging Gears, Grinding

Difficulty engaging gears often points to issues within the synchronizer rings or shift linkage. Grinding noises, particularly during shifts, signify a mismatch in gear speeds, frequently caused by worn synchronizers or low transmission fluid. These problems can also arise from a damaged clutch, impacting complete disengagement.

Troubleshooting, similar to diagnosing lawnmower engines, requires a systematic approach. Inspecting the shift linkage for looseness or damage is crucial. Internal inspection reveals worn synchronizers or damaged gear teeth. Referencing detailed manuals, like those for Honda engines, aids in identifying specific components and proper repair procedures.

III.C. Leakage: Identifying Fluid Types and Sources

Transmission fluid leakage demands immediate attention, as low fluid levels exacerbate wear and tear. Identifying the fluid type is paramount – manual transmissions typically utilize GL-4 or GL-5 gear oil, differing from engine oil or automatic transmission fluid. Leak sources vary; common culprits include worn seals (input/output shaft, differential), a damaged gasket on the transmission housing, or a cracked case.

Like maintaining a diesel engine, preventative checks are vital. Inspect seals and gaskets regularly. Similar to troubleshooting a PowerFlex40 drive, pinpointing the leak’s origin requires careful observation. Referencing service manuals, akin to those for Galaxy devices, provides diagrams and specific torque specifications for reassembly.

IV. Clutch System Repair

Clutch system repair is central to manual transmission functionality. This involves meticulous inspection and potential replacement of key components. Like assembling a complex device detailed in an installation manual, precision is key. Begin by disconnecting the transmission to access the clutch assembly. Thoroughly examine the clutch disc for wear, hot spots, or damage – mirroring the detailed checks outlined in engine service manuals.

The pressure plate requires scrutiny for warped surfaces or failing springs. Don’t overlook the throw-out bearing; noise often indicates impending failure. Replacing these components as a set ensures optimal performance, similar to updating software as per release notes.

IV.A. Clutch Disc Inspection and Replacement

Clutch disc inspection begins with visual assessment for cracks, breaks, or uneven wear – akin to checking components in a user reference guide. Measure disc thickness; exceeding wear limits necessitates replacement. Examine the friction material for oil contamination, which drastically reduces grip. Replacement requires careful alignment with the pilot bearing, mirroring the precision demanded in a soundbar manual’s installation steps.

Ensure the disc slides freely on the splines. New discs often have a coating needing cleaning. Proper installation prevents shuddering and ensures smooth engagement, much like troubleshooting steps in a manual.

IV.B. Pressure Plate Inspection and Replacement

Pressure plate inspection focuses on the diaphragm spring for cracks or fatigue – similar to scrutinizing parts in a lawn tractor manual. Check the release fingers for even travel and smooth operation. Heat checking, indicated by blue discoloration, signals potential failure. Replacement is crucial if any defects are found, preventing clutch slippage or incomplete disengagement.

Install the new pressure plate ensuring proper alignment with the dowel pins, mirroring the precision of a software installation manual. Tighten bolts gradually and evenly to specification, avoiding distortion; A faulty pressure plate compromises the entire clutch system’s performance.

IV.C. Throw-Out Bearing Replacement

Throw-out bearing (also called release bearing) failure manifests as noise during clutch pedal operation, akin to troubleshooting issues detailed in a troubleshooting manual. Inspect for roughness or play; any irregularity necessitates replacement. Lubricate the new bearing with high-temperature grease before installation, ensuring smooth engagement with the pressure plate fingers.

Proper alignment is critical, mirroring the precision found in a Galaxy A16 5G manual. Misalignment causes premature wear and noise. Carefully seat the bearing onto the input shaft, verifying free rotation. A worn throw-out bearing directly impacts clutch disengagement, leading to shifting problems.

V. Transmission Internal Repair

Internal repair demands meticulous attention, much like the detailed instructions within a service manual for a diesel engine. Begin with complete disassembly, carefully documenting gearset configurations. Inspect each gear for wear, chipping, or damage – a process akin to reviewing warranty information. Pay close attention to synchronizer hubs and sleeves, crucial for smooth shifting.

Bearing and seal replacement is paramount; use specialized tools for removal and installation, referencing guides similar to those for a PowerFlex40 controller. Thorough cleaning of all components is essential before reassembly, ensuring optimal performance and longevity, mirroring the care detailed in a lawnmower manual.

V.A. Disassembly and Inspection of Gearsets

Gearset disassembly requires methodical organization, akin to following a complex software installation manual. Carefully mark gear positions and orientations before removal to ensure correct reassembly. Inspect each gear tooth for pitting, wear patterns, or fractures – utilize magnification for detailed assessment. Check for backlash and ensure smooth rotation on the shafts.

Compare gear dimensions against manufacturer specifications, referencing technical documentation. Examine the gearset for any signs of overheating or improper lubrication. This detailed inspection, similar to troubleshooting a Bluetooth earbud, is crucial for identifying the root cause of transmission issues and planning necessary repairs or replacements.

V.B. Synchronizer Ring Replacement

Synchronizer rings, vital for smooth gear engagement, often wear during operation. Replacement demands precision, mirroring the delicate work of a soundbar manual’s setup instructions. Carefully remove the old ring, noting its orientation and any retaining clips. Thoroughly clean the synchronizer hub and cone before installing the new ring.

Apply a light coating of transmission fluid to the new ring to aid initial engagement. Ensure the ring is properly seated and secured. Inspect the synchronizer hub for wear or damage; replace if necessary. Proper installation, like a software update, is critical for restoring optimal shifting performance and preventing grinding noises.

V.C. Bearing and Seal Replacement

Worn bearings and seals contribute significantly to transmission noise and leakage, demanding attention akin to troubleshooting a complex device like a Smart TV remote. Carefully remove the old bearing using a bearing puller, avoiding damage to the surrounding housing. Inspect the housing bore for wear or corrosion; repair as needed.

Install the new bearing, ensuring proper alignment and lubrication. Replace seals concurrently, utilizing a seal driver for a secure fit. Like following a Galaxy A16 5G manual, precision is key. Verify seal orientation to prevent leaks. Proper bearing and seal replacement restores quiet operation and prevents fluid loss, extending transmission life.

VI. Shift Linkage Adjustment and Repair

Precise shift linkage is crucial for smooth gear engagement, mirroring the detailed instructions found in a software installation manual. Begin by inspecting all linkage components – rods, bushings, and pivot points – for wear or damage. Replace worn bushings, as they contribute to sloppy shifting.

Adjust the linkage to ensure accurate gear selection; consult the vehicle’s service manual for specific procedures. Incorrect adjustment leads to difficulty engaging gears or grinding. Like troubleshooting a Bluetooth earbud, methodical checking is vital. Tighten all connections securely, but avoid over-tightening. Proper adjustment restores crisp, confident shifting.

VII. Fluid Change and Maintenance

Regular fluid changes are paramount for manual transmission longevity, akin to the consistent maintenance recommended for a diesel engine. Use the manufacturer-specified fluid type – often a GL-4 gear oil – to avoid compatibility issues. Drain the old fluid completely, inspecting it for metal shavings, indicating internal wear.

Refill with the correct amount of new fluid, following the vehicle’s service manual. Check for leaks after the fluid change. Maintaining proper fluid levels ensures optimal lubrication and heat dissipation, preventing premature component failure; Like a lawnmower requiring seasonal upkeep, consistent fluid maintenance is key.

VIII. Troubleshooting Techniques

Effective troubleshooting begins with a systematic approach, much like using diagnostic flowcharts for complex systems. Start by identifying the symptoms: grinding, slipping, or difficulty shifting. Listen for unusual noises during operation. Inspect the clutch linkage for wear or damage.

Check fluid levels and condition. Utilize a scan tool if applicable, though manual transmissions often lack extensive electronic diagnostics. Refer to service manuals – similar to those for HP computers – for specific fault codes and procedures. Isolate the problem to either the clutch, internal transmission, or shift linkage before proceeding with repairs.

IX. Safety Precautions

Prioritize safety when undertaking manual transmission repair. Always disconnect the battery’s negative terminal to prevent accidental electrical shock, mirroring precautions found in appliance manuals. Support the vehicle securely with jack stands – never rely solely on a jack. Wear safety glasses to protect your eyes from debris.

Use appropriate hand tools and power tools, following manufacturer’s instructions, like those detailed in installation guides. Be mindful of heavy components; seek assistance when lifting. Dispose of fluids responsibly, adhering to local regulations. Consult relevant documentation, such as service manuals, for specific safety warnings related to the vehicle model.

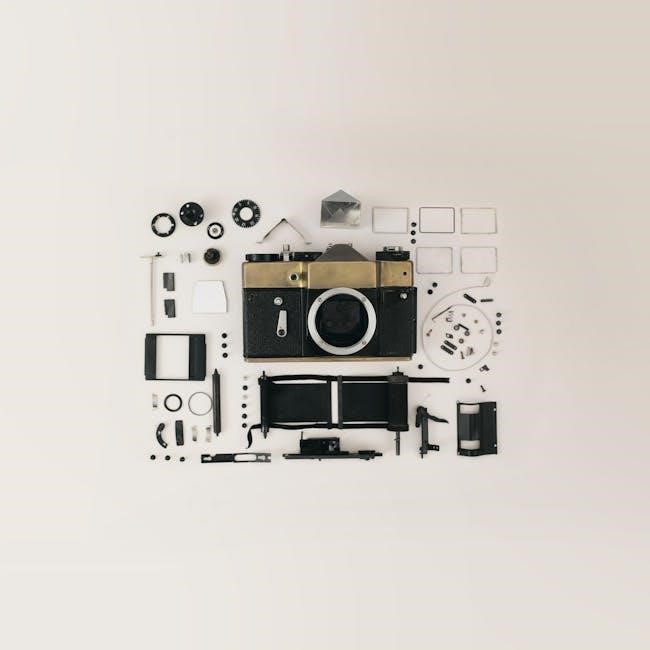

X. Specialized Tools and Their Uses

Manual transmission repair often demands tools beyond standard sets. A transmission jack is crucial for safely lowering and raising the heavy unit, similar to supporting lawnmower decks. Internal repairs require a slide hammer for removing stubborn seals and bearings, echoing techniques in engine maintenance manuals.

Specialized sockets, like Torx and triple-square, are common. Clutch alignment tools ensure proper disc centering during installation. A dial indicator helps verify runout on flywheels and discs. Diagnostic scanners, though primarily for automatics, can read related fault codes. Referencing detailed repair manuals, akin to those for complex electronics, is vital for correct tool application.

XI. Diagnostic Flowcharts for Common Issues

Effective manual transmission repair hinges on systematic diagnosis. Flowcharts begin with symptom identification – like grinding or slipping – then guide technicians through a series of checks. These resemble troubleshooting guides found in appliance manuals. First, verify clutch cable adjustment; then inspect the master and slave cylinders.

Grinding during shifts suggests synchronizer issues, requiring internal inspection. Slipping points to clutch wear. Leakage necessitates identifying fluid type and source. Flowcharts prioritize simpler checks before complex disassembly, mirroring the logical progression in software troubleshooting manuals, saving time and resources.

XII. Post-Repair Testing and Validation

Rigorous testing after manual transmission repair is crucial; Begin with a static check: engine off, cycle through all gears, confirming smooth engagement without unusual noises. Then, a road test is essential – assess clutch operation, shift quality, and overall performance under varying loads.

Monitor for slipping, grinding, or leaks. Compare post-repair behavior to pre-repair symptoms. Like validating software installations (akin to a software installation manual), confirm all functions operate as expected. Document test results, mirroring technical documentation procedures, ensuring a verifiable repair process.

XIII. Transmission Removal and Installation

Careful execution is paramount during manual transmission removal and installation. Disconnect all linkages, electrical connections, and driveshafts. Support the engine to prevent strain. Utilize a transmission jack for controlled lowering and lifting, mirroring the precision needed for installing complex systems like soundbars (HW-Q990D).

Inspect the flywheel and clutch components during removal. Upon installation, ensure proper alignment with the engine. Torque all bolts to manufacturer specifications, referencing owner’s manuals or technical documentation. Verify shift linkage adjustment before final fluid fill, akin to validating a new device setup.

XIV. Common Mistakes to Avoid

Rushing the process is a frequent error in manual transmission repair. Neglecting proper labeling of disconnected parts—similar to misplacing components during a complex installation like a Galaxy A16 5G—leads to reassembly issues. Ignoring torque specifications can cause damage, mirroring the consequences of improper setup detailed in user guides.

Failing to inspect related components (flywheel, pilot bearing) is another oversight. Overlooking fluid leaks or using incorrect fluid types compromises performance. Avoid cross-threading bolts and always double-check alignment, preventing issues akin to those found in troubleshooting manuals.

XV. Resources for Parts and Information

Locating reliable parts and information is crucial. Online retailers specializing in automotive components offer extensive catalogs, much like the diverse manuals available online—from Honda engines to Allen-Bradley drives. Manufacturer websites provide detailed specifications and diagrams, akin to the technical documentation for L-series Diesel Engines.

Automotive forums and enthusiast communities offer valuable insights and troubleshooting advice. Repair manuals (physical or digital) are essential, mirroring the usefulness of a Software Installation Manual. Consider parts recyclers for cost-effective options, but verify quality. Always cross-reference part numbers to ensure compatibility, avoiding errors like those in user guides.

XVI. Advanced Repair Techniques (e.g., Gear Replacement)

Gear replacement demands precision and specialized tools. This involves complete transmission disassembly, meticulous inspection for wear, and precise measurement of clearances – akin to the detailed steps in a complex Installation Manual. Heat treating damaged gears might be necessary, requiring professional expertise.

Proper gear meshing is critical; shimming and adjustments are often required, mirroring the fine-tuning described in a Troubleshooting Manual. Utilizing a press for bearing installation and removal is essential. Always adhere to factory torque specifications, similar to the precision needed for a Soundbar Manual setup; Thorough post-repair testing validates the work.

XVII. Future Maintenance Recommendations

Proactive maintenance extends transmission life significantly. Regular fluid checks, mirroring the diligence outlined in an Owners Manual, are paramount. Consider fluid changes every 30,000-60,000 miles, using the correct specification detailed in Technical Documentation. Inspect shift linkage periodically for wear, similar to checking a Smart TV Remote’s functionality.

Listen for unusual noises during operation – a skill honed by referencing a Troubleshooting Manual. Avoid aggressive shifting and “riding the clutch.” Proper driving habits minimize stress. Periodic inspections by a qualified technician, akin to a professional Lawn Tractor Manual service, can identify potential issues early.

No comment yet, add your voice below!